What is a ball bearing used for?

Key Design Features

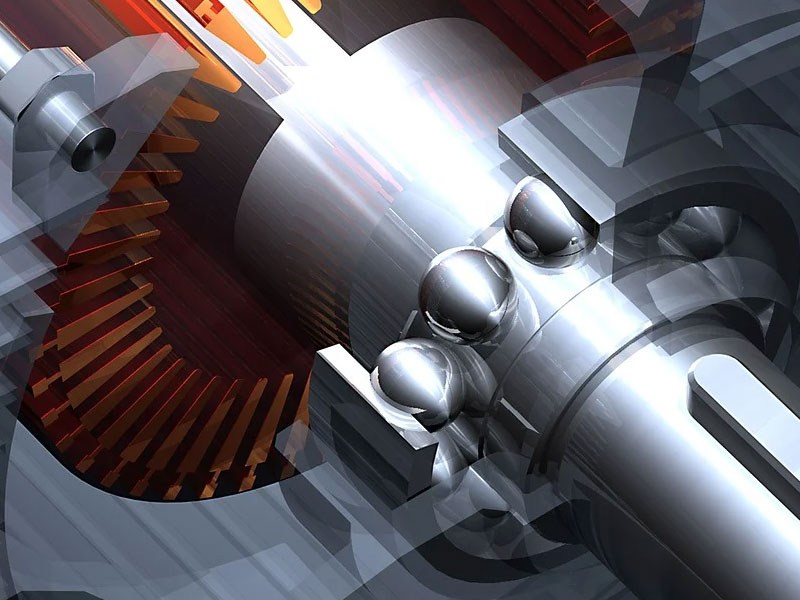

Inner/Outer Races: Grooved tracks guiding the balls.

Balls: Precision-sized spheres distributing load evenly.

Cage/Retainer: Separates balls to prevent contact and ensure smooth motion.

Seals/Shields: Protect against contaminants (dust, moisture).

⚙️ Fun Fact: Without ball bearings, modern machinery would overheat, wear out rapidly, and waste significant energy. They’re foundational to almost all rotating mechanical systems!

1. Reducing Friction

Ball bearings use smooth metal balls (typically steel or ceramic) rolling between two grooved rings (races).

This replaces sliding friction with rolling friction, drastically reducing energy loss and heat generation.

Benefit: Machines run more efficiently, consume less power, and generate less heat.

2. Supporting Loads

Radial Loads: Perpendicular to the shaft (e.g., weight on a wheel axle).

Axial/Thrust Loads: Parallel to the shaft (e.g., forces in a drill press).

Ball bearings handle both types, though specialized designs (like angular contact bearings) optimize axial load support.

3. Enabling Precision Rotation

Maintain alignment between moving parts, ensuring smooth, consistent motion.

Critical for high-speed applications (e.g., electric motors, turbines) where vibration must be minimized.

4. Extending Equipment Life

By minimizing friction and wear, they prevent premature failure of shafts, gears, and other components.

Lubrication (grease/oil) within the bearing further enhances durability.

Common Applications

Automotive: Wheel hubs, transmissions, alternators.

Industrial Machinery: Electric motors, pumps, conveyor systems.

Household Appliances: Washing machines, fans, power tools.

Aerospace: Jet engines, landing gear.

Consumer Goods: Skateboards, fishing reels, hard drives.

Robotics: Joints and rotating assemblies requiring precise movement.